Technical Papers - Internal Coating

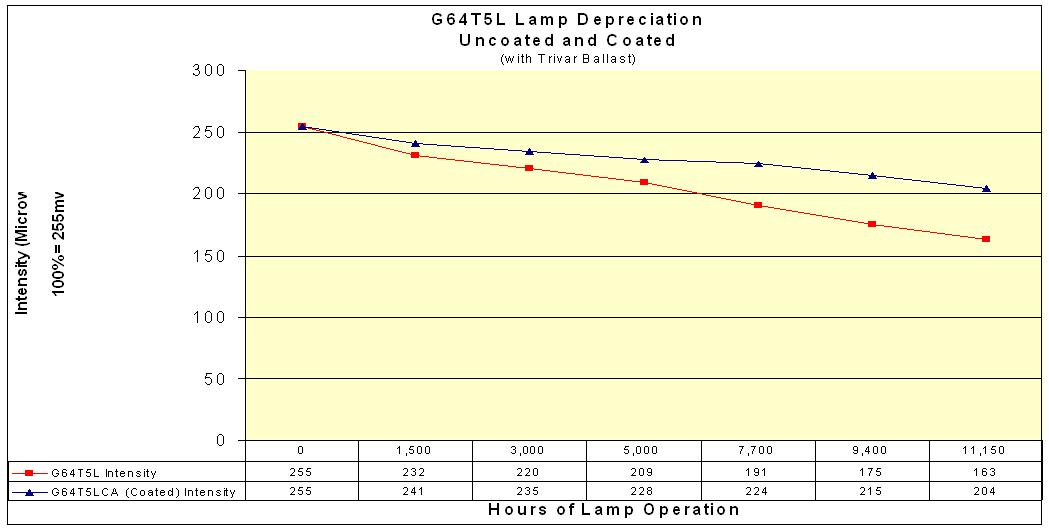

Low pressure UV mercury lamps have always been limited by the effects of lamp depreciation throughout their lifetime. FLT has developed coated lamp technology to improve performance over the lifetime of our lamps.

Low pressure UV mercury lamps have always been limited by the effects of lamp depreciation throughout their lifetime. FLT has developed coated lamp technology to improve performance over the lifetime of our lamps.

First Light Technologies, Inc. coated lamps (designed by “CA” after the quartz type) incorporate an internal coating to reduce the process of darkening of the quartz envelope.

This is the result of a weak electrical field that is formed between the lamp arc and the quartz wall. Mercury ions are accelerated within this field and eventually form mercury oxide through the operation of the lamp (HgO). The mercury oxide attaches itself to the uncoated lamp wall which causes the lamp body to turn brown and/or dark (i.e solarization). This build-up can reduce the uv output of the lamp by as much as 50% in the first year of lamp operation. Specific applications, especially those in cold water, tend to accelerate this chemical reaction.

First Light’s internal coating prevents the build-up of mercury oxide on the lamp wall.

This coating process significantly increases the lifetime of our lamps to more than 12,000 hours with less than 20% drop in UVC output. (see graph)